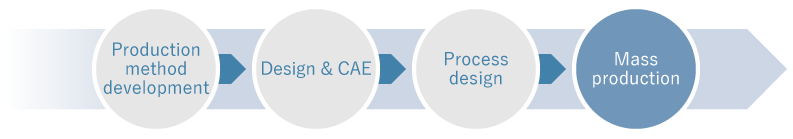

Ahresty is engaged in continuous research and development efforts to develop new materials and production methods, staying one step ahead of customer needs that demand advances in die casting technology.

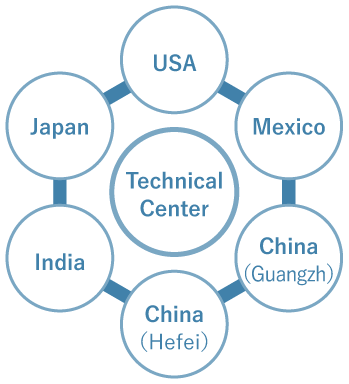

The Technical Center is the nerve center of our technology development efforts. It also functions as a support base, helping us to achieve consistent production quality at all of our production facilities worldwide.

Head Office and Technical Center (Toyohashi, Aichi)

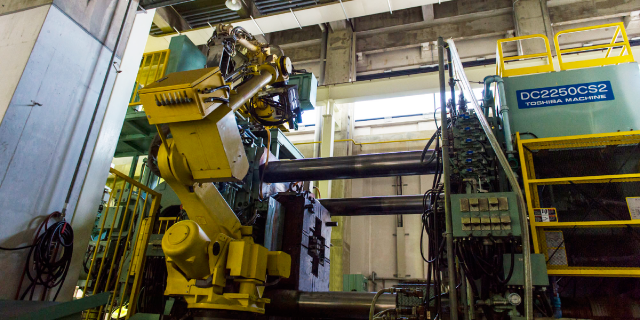

2,250 ton casting machine (for testing purposes)

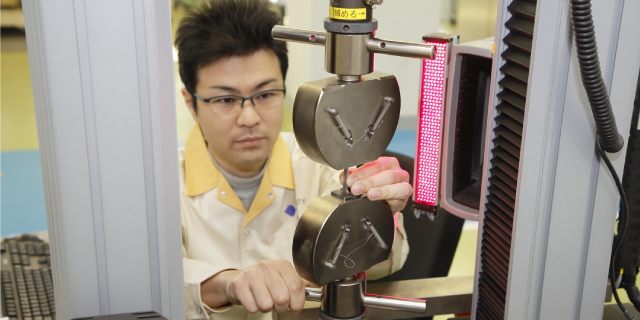

2,250 ton casting machine (for testing purposes) Material property assessments carried out by various testing machines

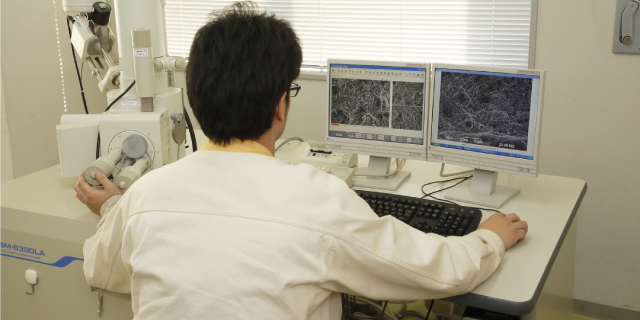

Material property assessments carried out by various testing machines Observation and analysis using electron microscopes

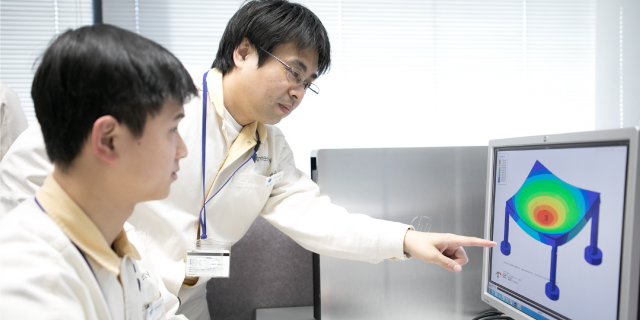

Observation and analysis using electron microscopes Excellent design and analysis setup

Excellent design and analysis setup Optimal shape achieved through CAE

Optimal shape achieved through CAE High-productivity manufacturing process support framework

High-productivity manufacturing process support framework Setting optimal production conditions

Setting optimal production conditionsAhresty is working every day to research and develop new production methods and technologies that will enable greater quality and higher efficiency in production.

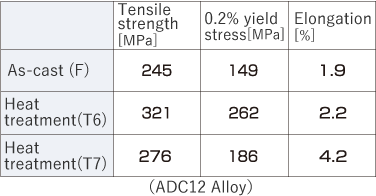

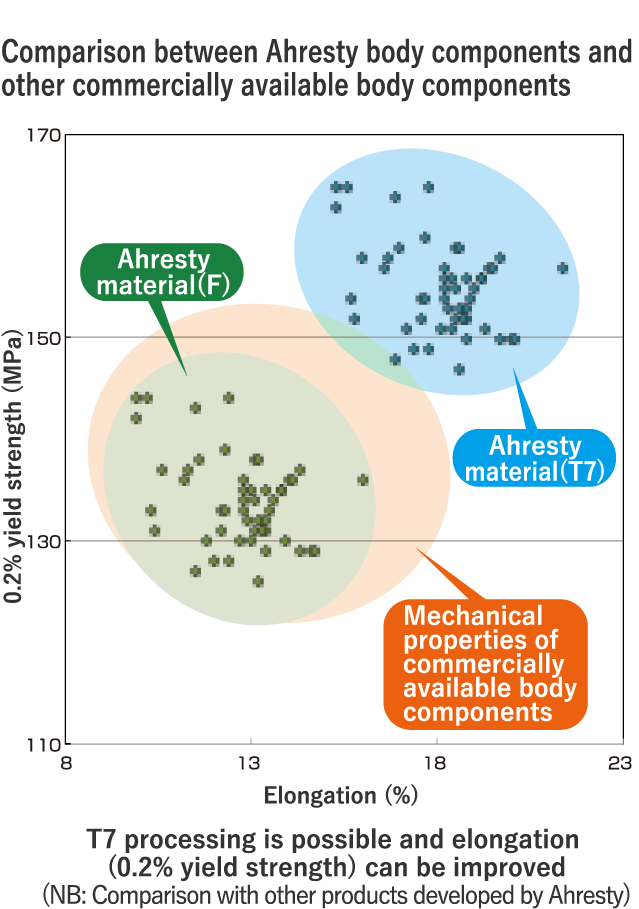

Ahresty’s casting method enables T7 heat treatment and improves on the elongation performance (0.2% yield strength) demanded for automobile body components, etc.

Increasing the level of vacuum inside the cavity (in comparison with low-pressure die casting) means that Ahresty’s method can also be applied to the production of higher quality, large-scale thin wall casted products.

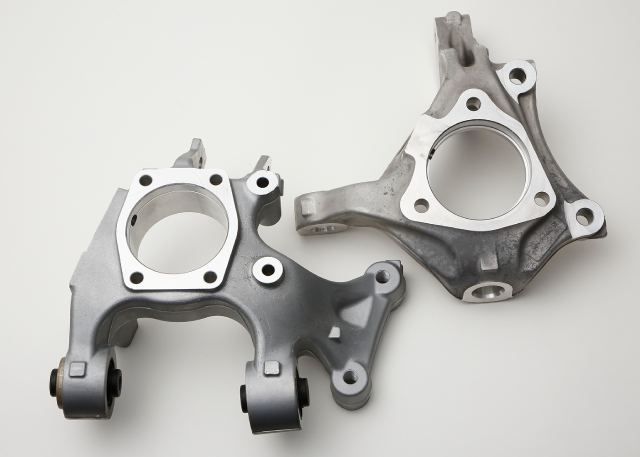

[Components to which this method can be applied]

Chassis, body and EV/FCV case components

Achieving a whole new class of quality that exceeds conventional expectations for die cast products

In comparison with regular die casting methods, Ahresty’s casting method creates products with greatly superior mechanical properties. Ahresty was awarded the Minister of Economy, Trade and Industry Prize for this casting method in 2004, as a proprietary production method that has greatly expanded the scope of applications (with a primary focus on undercarriage/ suspension-related products).

[Components to which this method can be applied]

Suspension components, engine and transmission mountings, brake components

Improved strength, welding and hardness solved by heat treatment (T6)

This method of casting replaces the air in the cavity with oxygen, thereby greatly reducing gas defects. Application of this die casting method to automobile components enables us to contribute to reducing weight and respond to tougher fuel efficiency requirements.

[Components to which this method can be applied]

Various mounting and member components, brackets, pressure-resistant parts