Aluminum die casting is a manufacturing process that uses lightweight, easily recyclable material aluminum , offering wide design flexibility and high productivity.

Having global production capability, Ahresty seeks to brighten our planet’s future by improving fuel efficiency and electric mileage, CO2 emissions reduction, and the creation of a recycling-oriented society, through our lightweight technology and usage of environmentally friendly material.

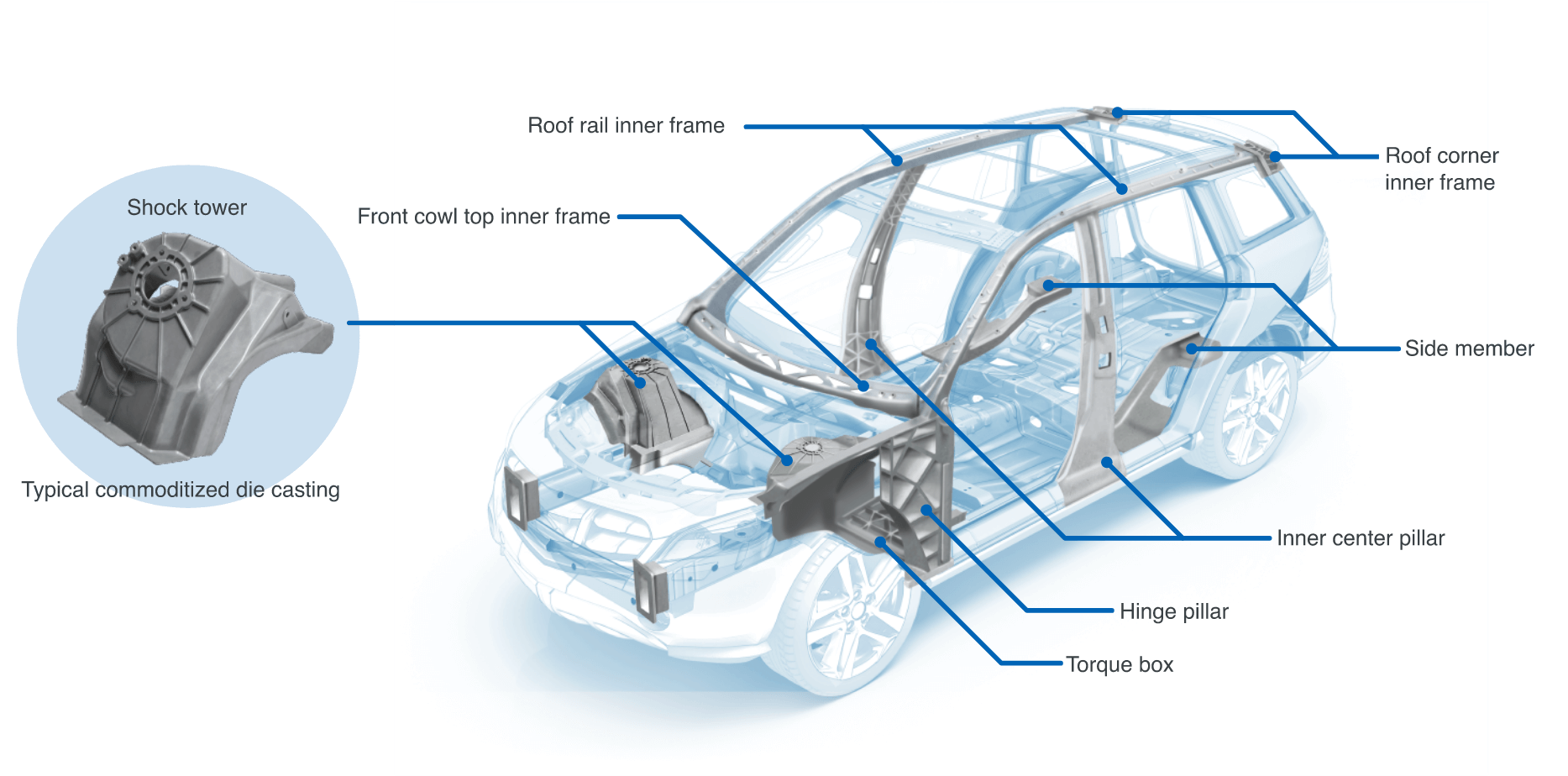

[ Applicable products ]

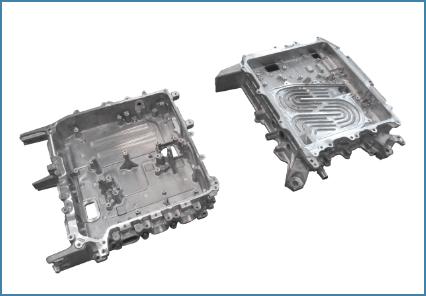

EV battery cases, further integration of vehicle body components

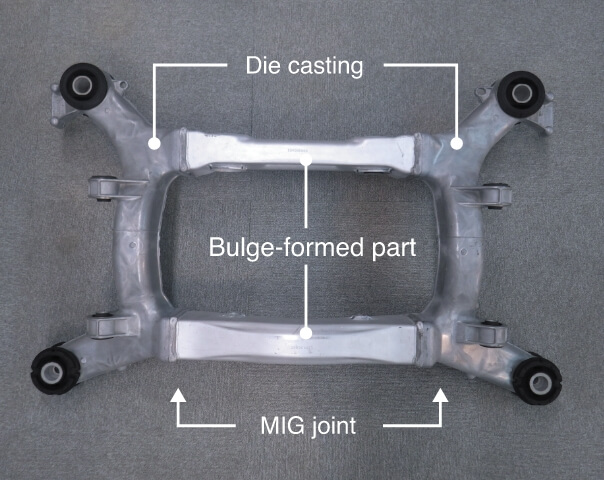

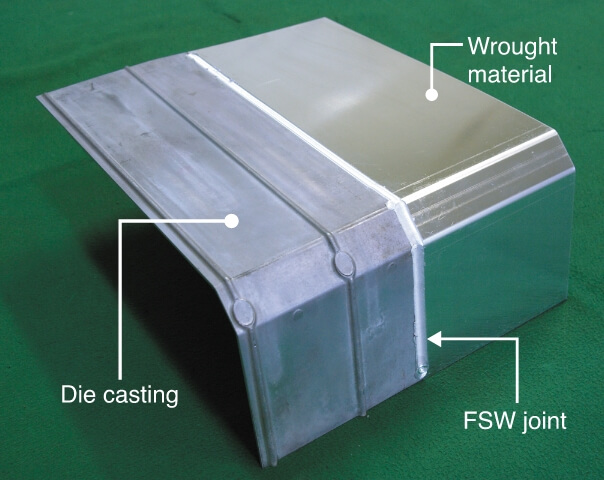

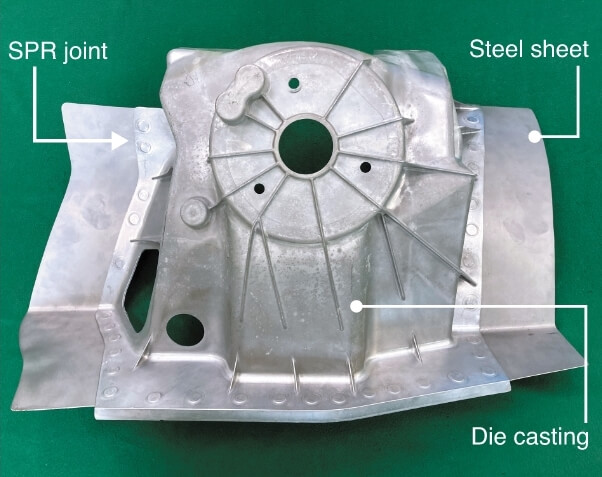

Research and development regarding joining conditions for MIG, FSW, and SPR joining technologies

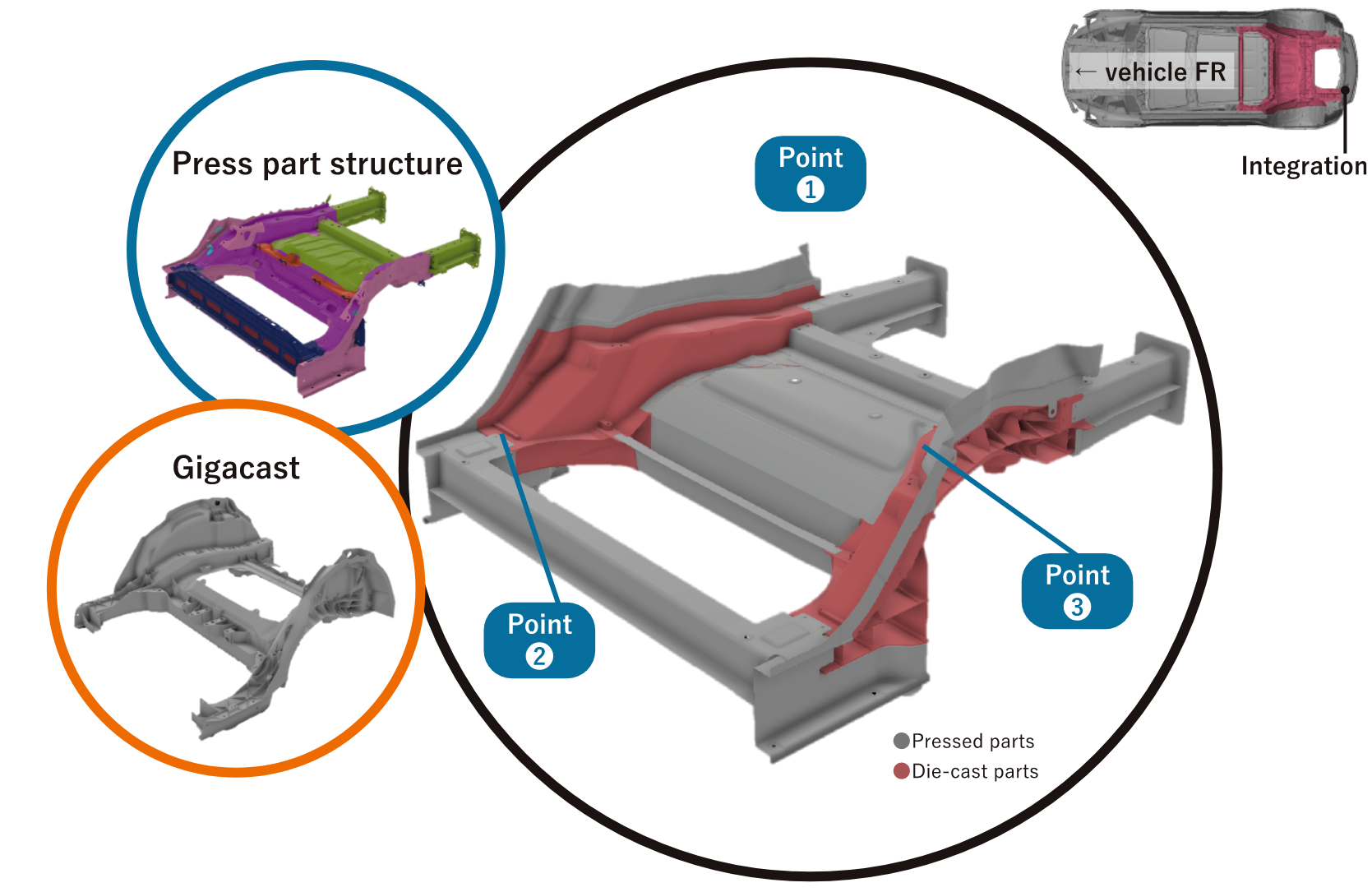

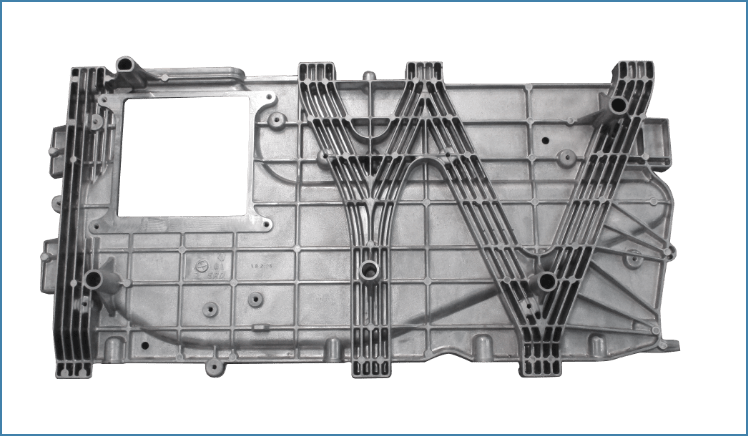

SUBFRAME

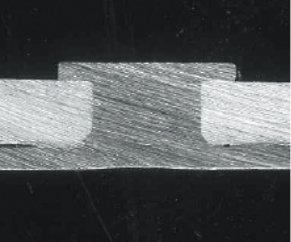

FSW test sample

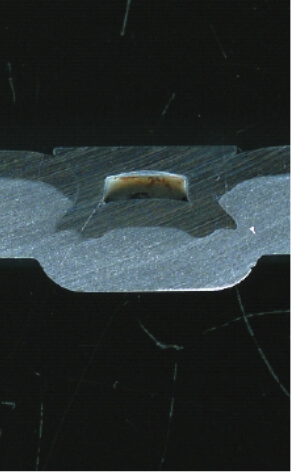

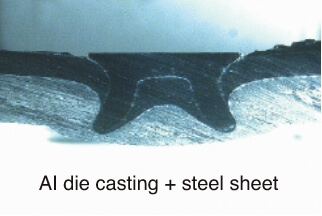

SPR test sample

Joining of die castings and steel sheets are mandatory requirement for production of multi-material body. Joining technologies are benchmarked and compiled into database for future usage.

| Rivet | Self-drilling screw | Element welding | Solid-state welding | Adhesion | |

|---|---|---|---|---|---|

| SPR | FDS® | FlexWerd® | FSW | Adhesive technology | |

| Butt welding | Lap welding | ||||

|

|

|

|

|

|

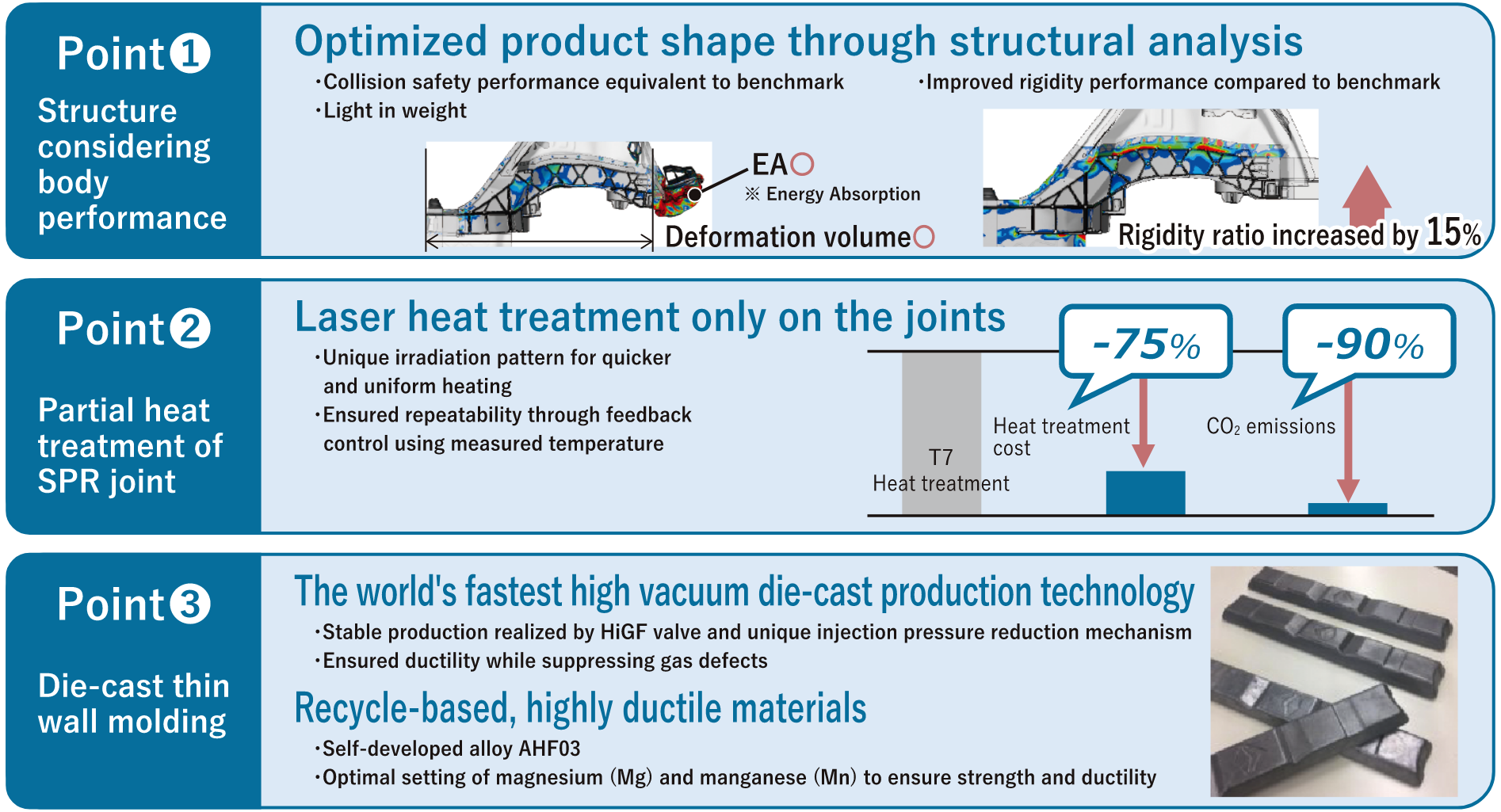

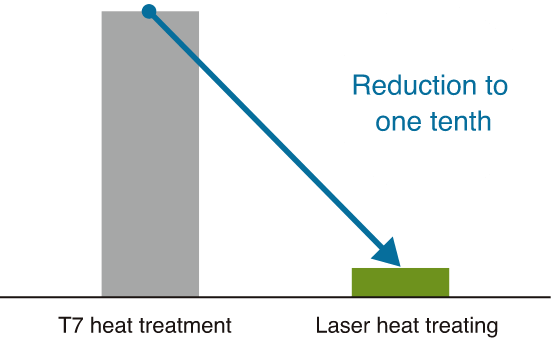

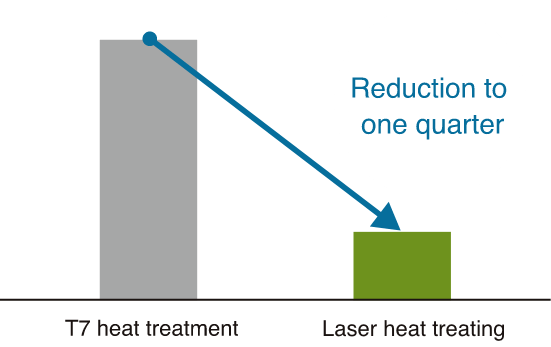

Newly invented partial heat treatment method which can replace T7 heat treatment incurred on die casting to prevent cracks occurring on uniting surface while joining with steel sheet (e.g. SPR).

[ Applicable products ]

Vehicle body components

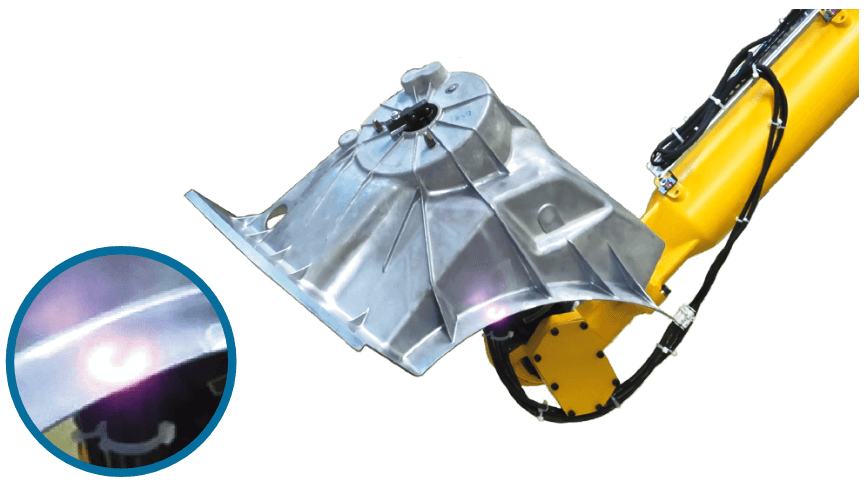

Laser heat treatment of shock tower-type product

・Capable of ensuring the required ductility

by short-time laser heating

・Capable of applying heat treatment while controlling

the temperature at the heating point

(Heat treatment of 40 points located at edge

of a product can be completed in 120 seconds.)

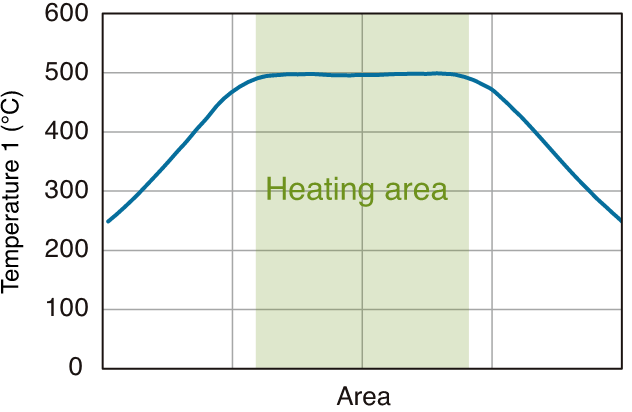

Heating uniformly

in the heating area.

Temperature distribution of the laser heating area

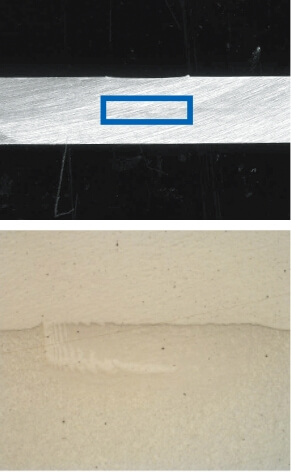

Product without heat treatment

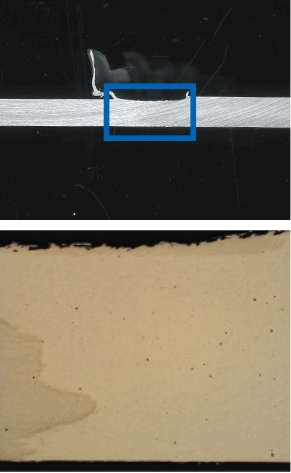

Product with laser heat treating

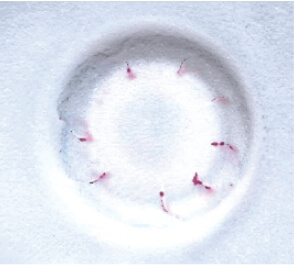

Laser heat treating can

prevent cracking at SPR joints.

Aluminum surface after SPR

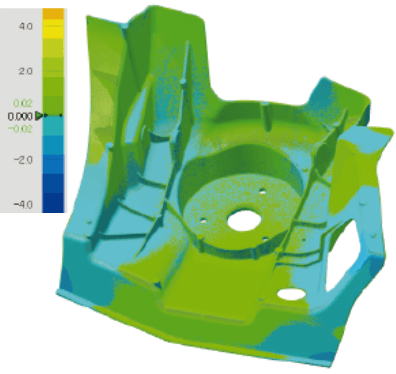

Product deformation

< 1.1 mm

⇒Dimension corrections are unnecessary.

Deformation after laser heat treating

CO2 emissions

Heat treating costs

Other effects

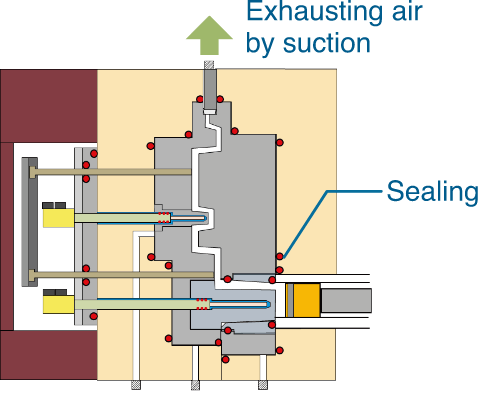

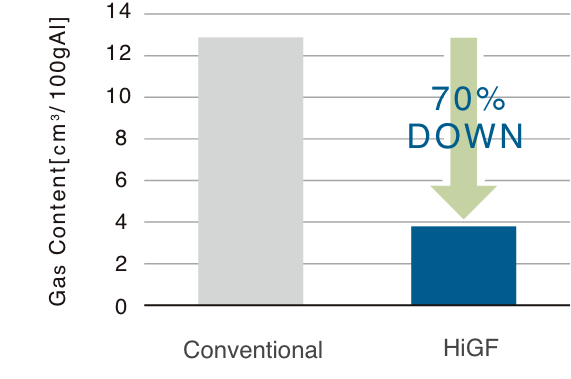

In comparison with conventional vacuum die casting, this casting method enables the production of higher-quality die castings by rapidly exhausting air from the cavity creating vacuum ranging 2 to 3 kPa.

[ Applicable products ]

Vehicle body components, subframes, battery cases, etc.

・Our unique exhaust valve structure and the improved sealing performance of the dies and injection mechanism enabled achieving high vacuum status.

・A low gas content in a product enables T7 heat treatment and improves elongation and 0.2% yield strength.

HiGF Method Simplified Diagram

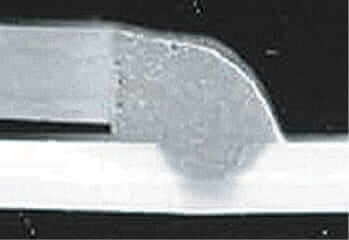

Gas-content comparison with conventional technology

Elongation and 0.2% yield strength every heat treatment

・Enabling casting of large, thin-walled products

・Enabling usage of various joining technologies

Low gas content in the product eases welding difficulty.

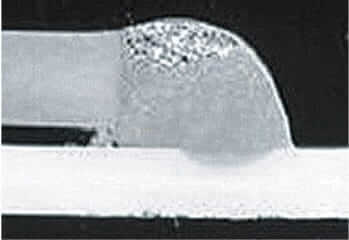

Weld bead of a conventional method die casting

Weld bead of a HiGF method die casting

Substantial reduction of pores in a product

SPR joint cracking does not occur even in an as-cast material, allowing joining of dissimilar materials.

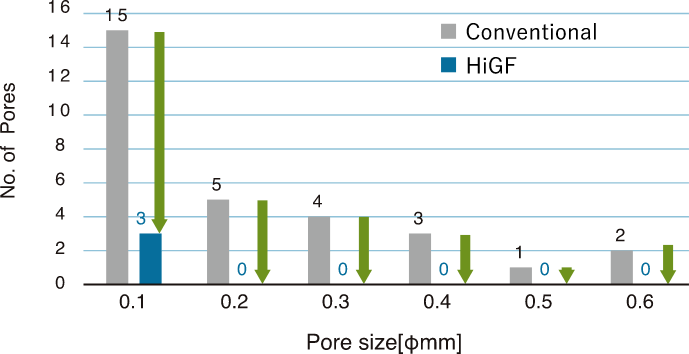

Cracking after SPR in a die casting made by the conventional method

No cracking after SPR in a die casting made by the HiGF method

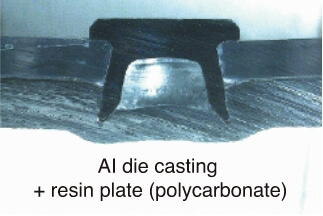

| Upper plate on the flange side | Resin plate (polycarbonate) t2 | Steel sheet t1.2 |

| Lower plate on the die side | AI die casting2.4 | AI die casting t2.4 |

| Total thickness [mm] | 4.4 | 3.6 |

| Interlock 1 [mm] | 0.27 | 0.29 |

| Interlock 2 [mm] | 0.29 | 0.35 |

| Average [mm] | 0.28 | 0.32 |

| Cross-sectional photo |

|

|

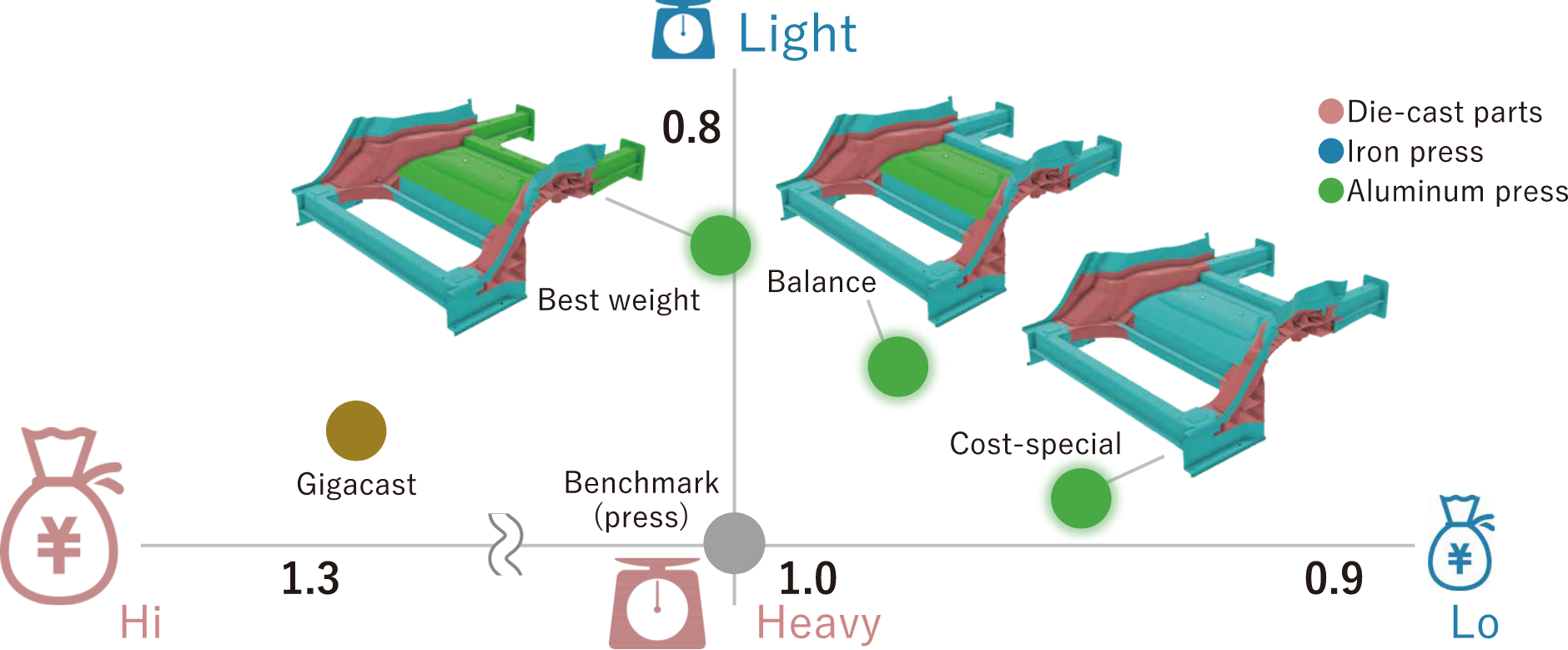

| Advantages | Stiffness | Improvement in the stiffness of parts due to cross-sectional shapes that capitalize on the flexibility in rib shape and wall thickness |

|---|---|---|

| Shape Flexibility | Enabling integral molding by capitalizing on the flexibility in shape, whereas press-molded products require multiple parts to be joined |

|

| Weight Reduction | Enabling weight reduction by capitalizing on the properties of aluminum in terms of specific stiffness and specific strength |

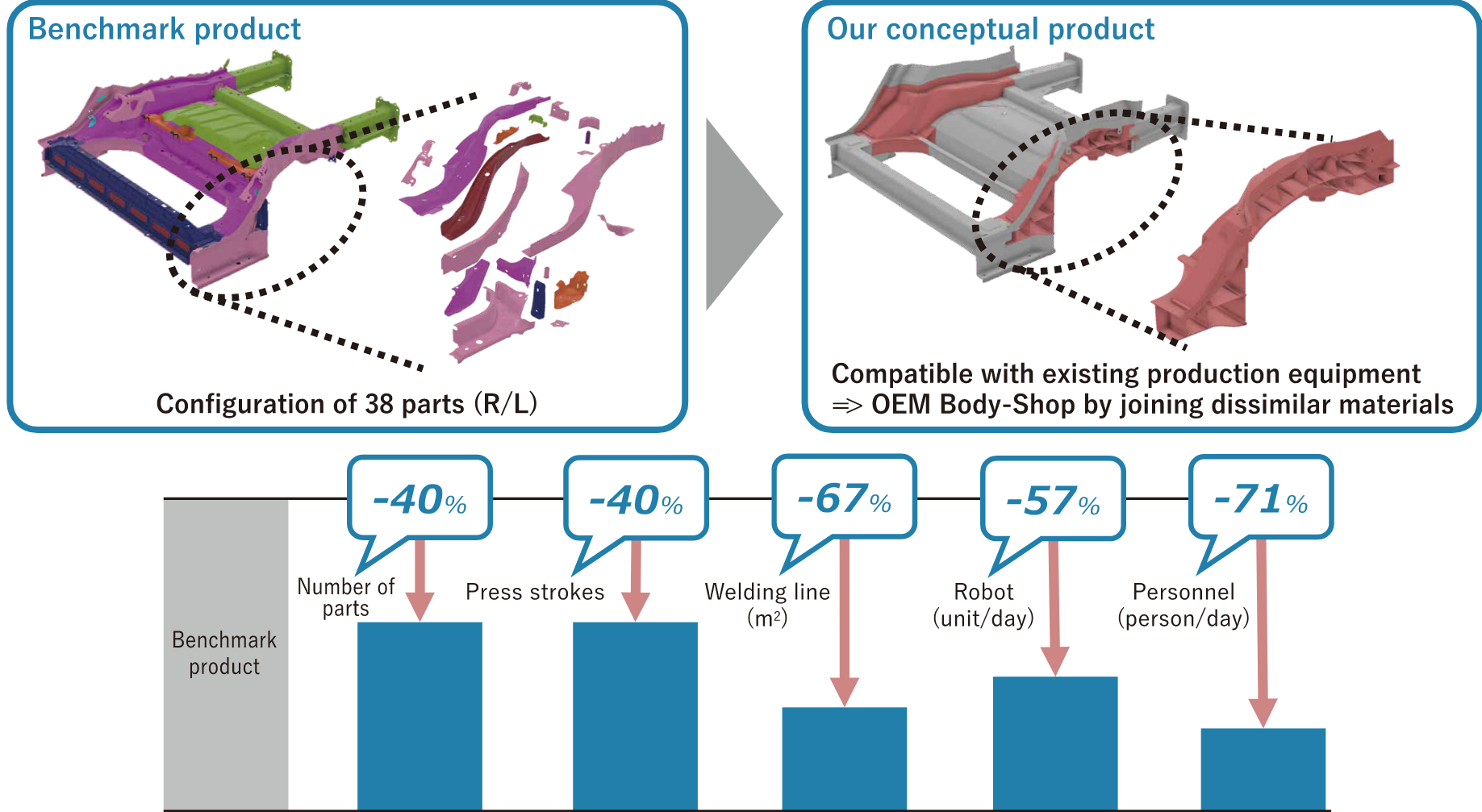

Utilizing our proprietary technology for the production of vehicle body components

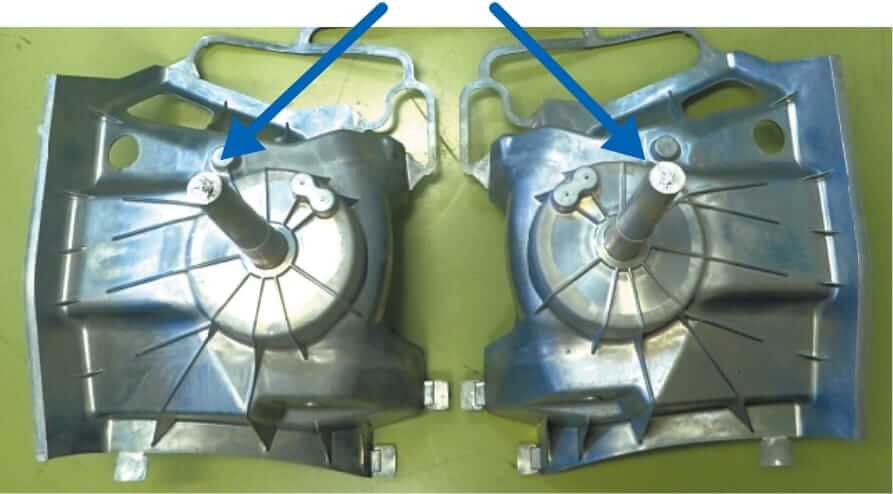

We are proceeding with the application of our proprietary technology, “HiGF method,” to the production of vehicle body components. Our ingenuity in sealing the mold parting surfaces has increased the vacuum level inside the cavity and short charging time of molten metal enabled the production of high quality die castings. Furthermore, the adoption of multi-cavities and a center gate, which allows molten metal to be charged with lower pressure and less energy, enables two-piece production with one injection, resulting in improved production efficiency.Ahresty has successfully achieved the world’s top-class production speed during development of shock towers.

Center gate (allowing molten metal to be charged with lower pressure and less energy)

Shock towers produced by the HiGF method

(2 pieces per injection)

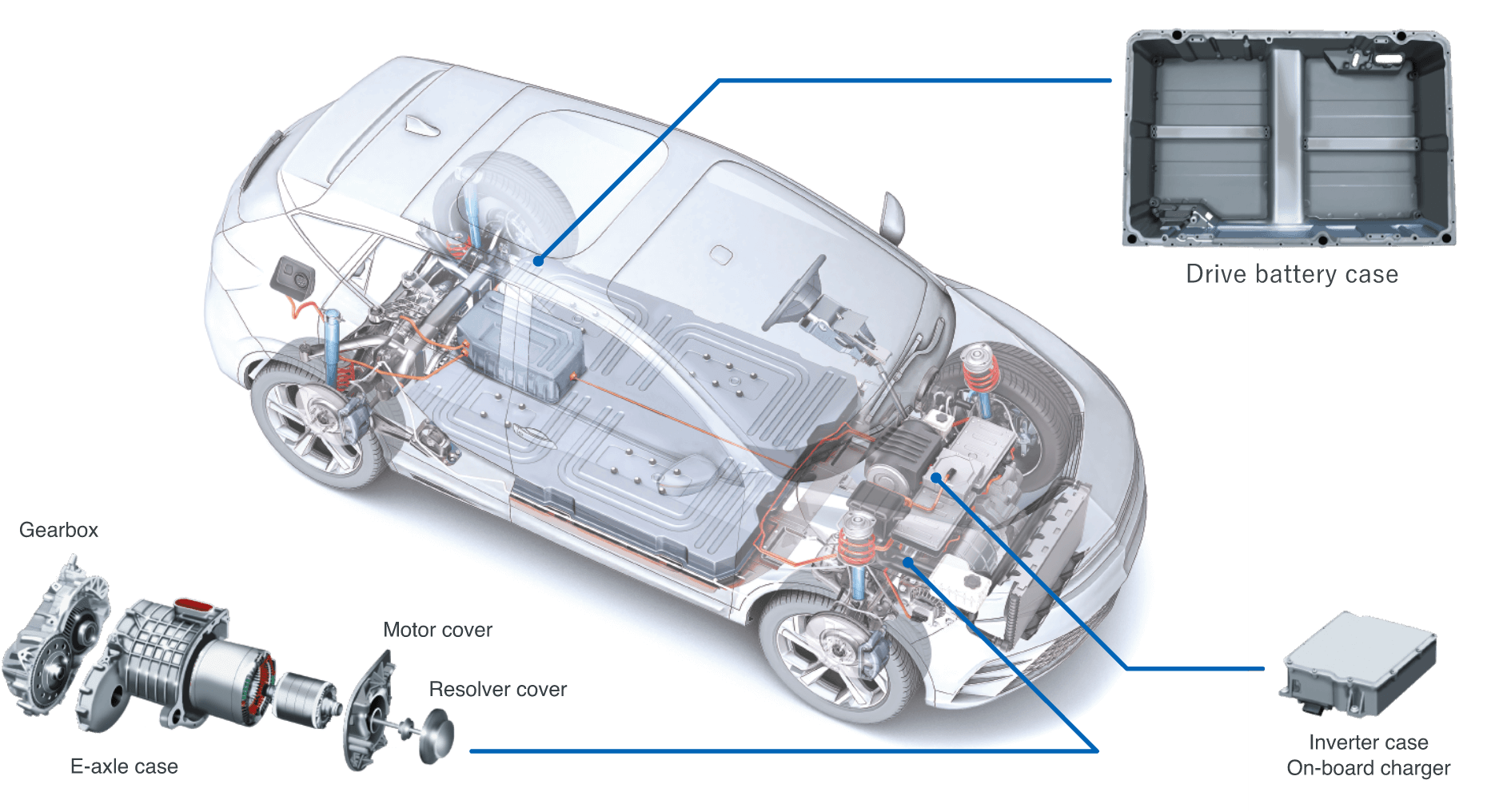

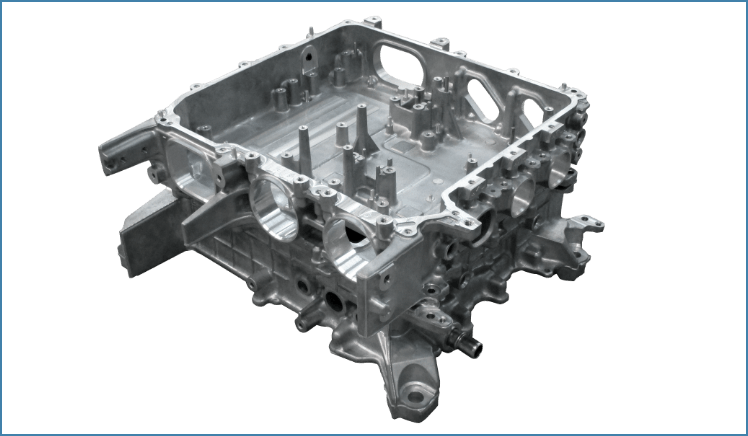

Die castings that hold the key to spreading the use of next-generation eco-cars, namely, electrified vehicles

Contribute to development of next-generation eco-cars by utilizing our experience acquired through the production of various types of electrification components

bz4X(TOYOTA)

SOLTERRA(SUBARU)

CR-V(HONDA)

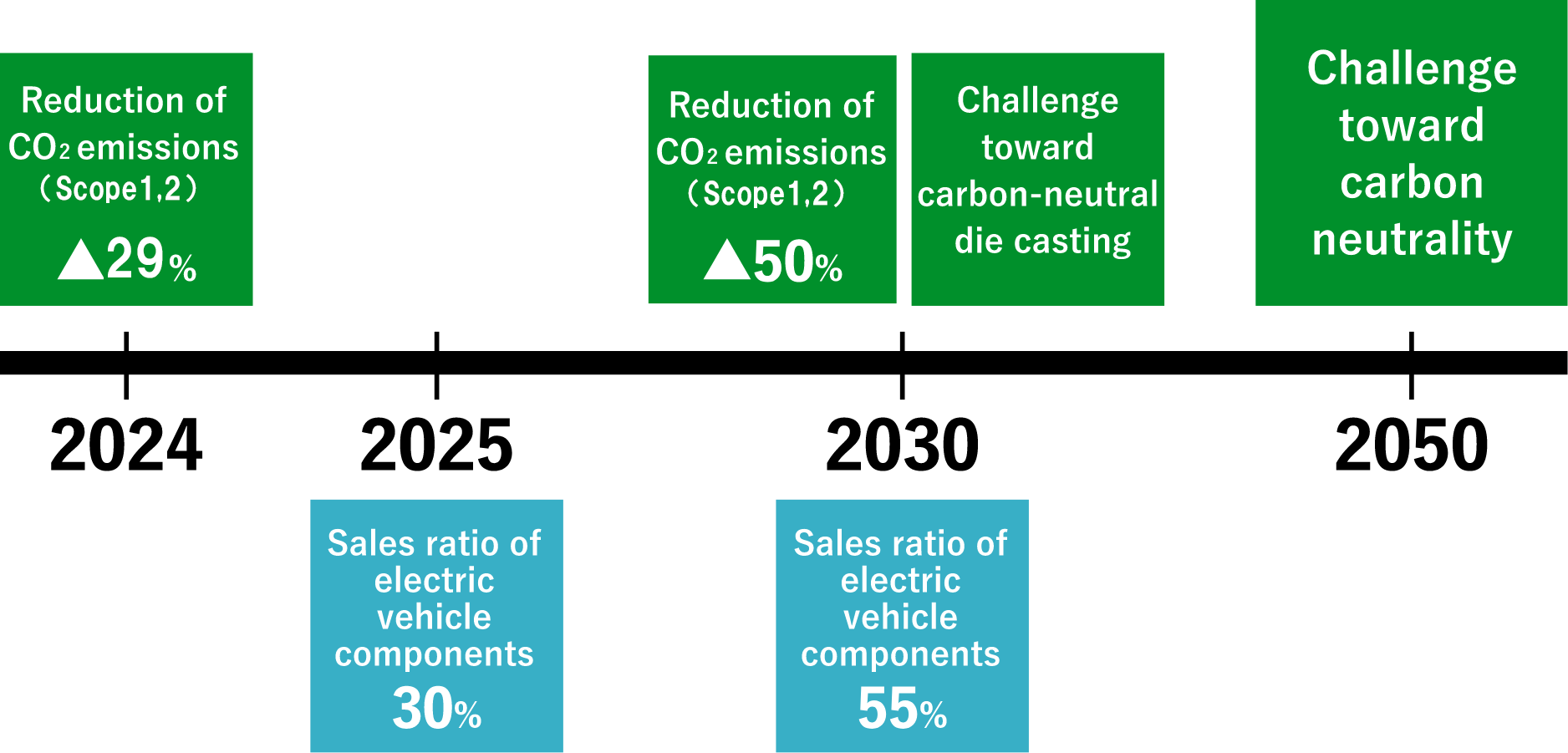

Aluminum is a light metal whose specific gravity is about one-third of that of steel (about a half in product comparison). Meanwhile, over 90% of Ahresty’s products use secondary aluminum alloy made from recycled aluminum scrap. The amount of energy and CO2 generated during the production of secondary alloy is equivalent to merely 3% of that generated during refining a raw material (bauxite) into new raw metal (aluminum primary alloy).

By taking advantage of the lightweight and excellent environmental properties of aluminum, we seek to brighten our planet’s future.

* Compared to FY 2013

※Group overall, Scopes 1 and 2